introduce to PP pipe fitting mold

Published on :2020-03-13

You need to understand that pp pipe has its own molding characteristics, and injection molding of pipe is a very common molding method. At present, most plastic pipes and fittings in China are made of PP materials. PP fittings are most widely used in industrial production. PP pipe fittings have good technical and economic benefits, and mainly have the following advantages:

- PP pipe fittings are easy to install and improve the bonding strength. Its specific gravity is 0.91, which is about 1/9 of the weight of iron, making it easy to cut and melt on site, but it should avoid pp pipe injuries during handling and installation.

- The life of pp pipe fittings is very long. In a certain temperature and concentration range, it can withstand the erosion of various highly corrosive media and organic solvents, and has low fluid resistance. Great progress has been made in plastic pipes of the same specifications. On the one hand, the resistance to stress cracking and scratch resistance are poor.

- Excellent heat resistance and low temperature resistance. Can be used at temperatures up to 90 ° C, also suitable for use at low temperatures.

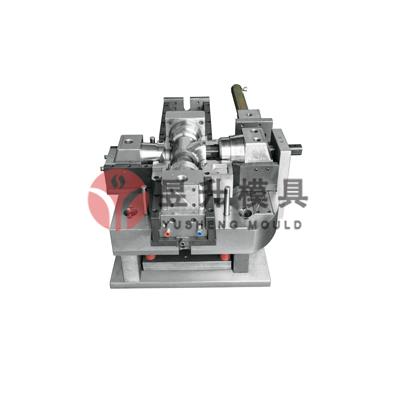

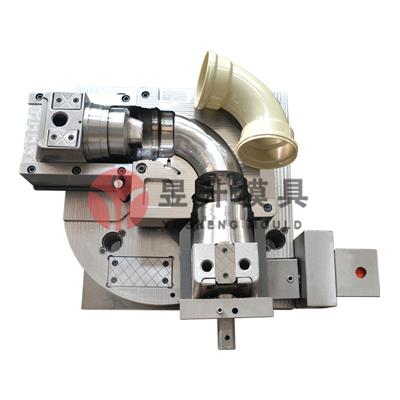

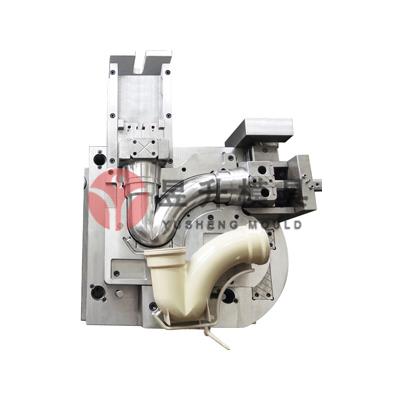

Yusheng's PP pipe fitting mold has a variety of standard foldable core materials, with diameters ranging from Dia32mm to Dia160mm. In this way, we can improve delivery time. Starting from the normal 120 days, we can now deliver 50 different molds within 60 days. What process is used to process the tube mold? What material and hardness should be selected for mold steel? Is the cooling design in the mold perfect?