How to design a crate mold?

Published on :2020-11-05

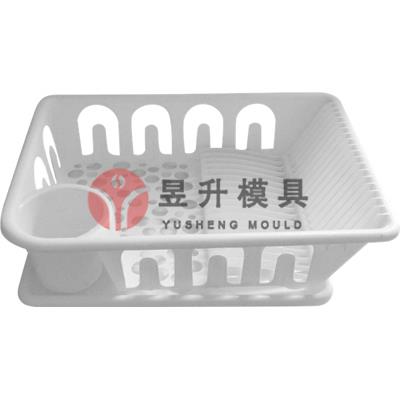

Crate mold is a kind of mold with relatively technical requirements. In addition to processing and experience, the most important thing is mold design. In order to be able to process products with standard accuracy and good quality, some regulations and requirements must be followed, so how to design a crate mold?

What are the technical requirements in the design of crate molds?

Crate mold design requirements include: mold structure type, mold external size, number of cavities, runner form, product demolding method, etc.

Generally, the crate mold is a four-slider structure. The slider is heated and easily damaged during the continuous sliding process. Therefore, the material requirements of the slider are relatively high. The inside of the slider must be connected to the waterway. The waterway must Reasonable, so as to improve the production cycle of the product, the contact between the slider and the core must be added with wear blocks.

The number of cavities of the mold: Generally, crate molds can only produce one, and those who can produce 2 are considered as relatively powerful companies. Yusheng can produce 4 each to ensure product production efficiency and save individual products. Processing cost.

Runner: Yusheng uses a multi-point gate hot runner. After the mold is opened, there will be no product waste, which directly saves the cooling time of the runner and effectively improves production efficiency.

How long does it normally take to manufacture crates?

Mold manufacturing cycle: 20-30 days for small molds, 40-90 days for medium molds, and 100-120 days for large molds. The exact manufacturing cycle of molds also depends on technical requirements such as the structural accuracy of the crate mold;

What is the price of the crate mould?

The price of plastic molds depends on the complexity of the product, the level of quality requirements, the equipment used for mold processing, the size of the mold, the number of mold cavities, the runner method, the demolding method, and the material selected for the mold.